Woods and Hardware, Art and Time

The wood we use, reclaimed from barns, flooring, and walls from olde homes, sheds, and stacks, has been exposed to the elements for decades or even centuries.

Woods, Hardware, Our Style, and More!

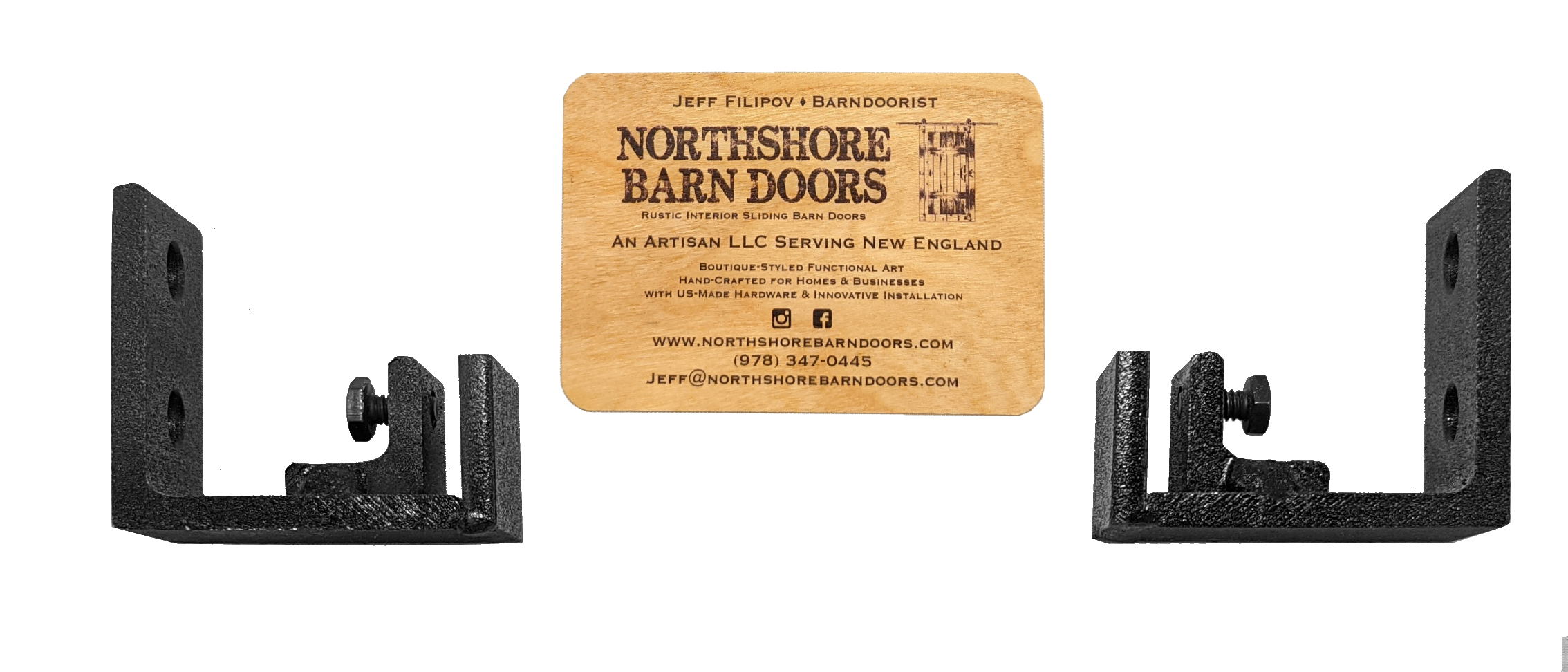

The Barndoorist usually works with steel coated in a rustic black finish. Some silver styles can be worked on but black is the typical style being worked with. While some wheel hangers may be similar to those found on the market, they are retrofitted and recoated at our shop during assembly. Bolt heads and lock nuts are the most commonly used pieces and bolt lengths are custom cut for each door width. These are also coated in rustic black in the shop and touched up on site when installing doors.

The Barndoorist uses bracket parts for some projects and fashions his own hand-made custom brackets for many door systems. Some are made from 1/4" thick steel and some are even more robust, using 3/8" thick steel. The Barndoorist often uses a metal bender, metal saw and sometimes a large hammer to shape some pieces. Other pieces may need to be sent out. Rails can be ordered and retrofitted to match our style, or can be fashioned from US steel stock in our shop. Spacers and stoppers can often be fully customized depending on job needs. Handles such as the rail road spike are drilled and colored black accordingly.The Barndoorist is always experimenting with new ways to make parts and has developed a new wheel hanger and some brackets for bypass doors using MIG welding.

Northshore Barn Doors prides itself on both making many of its own custom parts for doors and also retrofitting any part that may have been found on the market for use in a door project. We do not just buy and resell kit parts, rather, we rework pieces that make the hand-made rustic look come alive and fit perfectly into your home, retail or office space.

Here are pictures of some of the wheel hangers used on our doors and some handles we offer with all projects. Other handles and parts can be used and this is discussed when we meet and in subsequent communications during project planning. Some wheel hangers may seem familiar, but note that we re-coat the black surface, and we use our own bolts and more secure lock nuts than ones sold online or in store-bought kits. Everything is made black using rustic coatings and sometimes new holes are bored in parts such as rails, brackets and wheel hangers in order to accommodate for larger, heavier and thicker doors.

The Barndoorist creates and retrofits hardware, usually done in a rustic black metal finish, and customizes parts for each project. Pictured here are just some examples of the specialized parts you might choose from. These may change but the quality is always there!

Northshore Barn Doors:

We offer custom sizes of doors based on your particular entryway size, which are never standard in New England, even in many new homes!

We offer complete on-site installation. We have an innovative bracket-mounting method that does not require a ledger up top! We can mount rails in several ways including bypass.

Our metal parts are adjustable!

We have been focusing on making and installing barn doors for a generation.

We often offer mockups showing you visuals of what your door will look like opened and closed, and in other styles or colors available.

We offer continued service if something we install needs adjustment. We respond right away!

Our hardware is made from US metals and is locally sourced. Everything is assembled in our Amesbury, MA workshop. We do not use the KIT parts sold at home centers or from cookie cutter online sources.

Our metal parts are robust and designed to reflect the look and style of high-quality hand-crafted barn doors.

We include choices of several front and back handle types, we make and source, our rail stoppers with pads, our custom-made varieties of base roller guides, and single-side eye hook latches with every installation.

We solved the gap issue behind doors and we can also clear over most wall obstructions all at the same time! Ask us about “side boards” and how these customized elements work in tandem with your customized sliding barn door project.

Our wood styles and finishes include rustic, semi-rustic, modern, and industrial farmhouse typically created with aged pines which we hand-craft in our workshop.

Communication is key! We detail the entire project and make payments easy with an initial 50% deposit and one final payment when installing. There are no upcharges and everything is explained and outlined as we get going. Glass and steel elements added will increase costs but we can design anything for your needs.

We offer locally supplied tempered glass in several styles.

We weld and innovate metal parts and fittings in our workshop.

Our focus is functional art and quality. Your Barndoorist takes pride in the workmanship so that you love your centerpiece of enjoyment in your home or business!

Our style is robust and bold. Barn doors are wider than an entryway and often a bit taller. Our wood is thicker than new stock that others may use, and so your door is easy to roll but it is solid and strong. We can even govern the wheel roll.

Online and Big Box Stores

Most barn doors and kits you see in stores and online are mass-produced and do not fit all entryways.

All the kit parts you see are likely made in China, and while some pf these parts look nice, we find their steel is of a lesser quality and they often fake it with plastic and aluminum where real US steel should be used instead.

Kit parts are limited in style and versatility. The wheel arms are not adjustable and can become loose over time, which can cause the door to tilt or drag.

Home center and online-supplied doors are typically thinner, new stock which is often not fully dried and is therefore going to move and change once installed. The doors are often flimsy by design.

You need to install everything and add a ledger up top in order to mount the rails. Even experienced builders complain about many of the unknown nuances of installing barn doors, and as simple as they seem, this can take several hours one would rather spend doing something else. Installing barn doors requires experience with how every element works in tandem and this can frustrate even the best DYI person or builder.

With no one to guide installing, many parts or features are left out without even knowing they may be needed. Your barn door should look like it had been easy to install and they be easy to move, but in order to have this, a qualified and experienced Barndoorist installer knows how to do the complicated things behind the scenes to achieve this result.

Kit doors have gaps behind them. Many people do not order the right width slab. No one is there to help compensate for non-level floors or wavering in wall and trim that can occur in older homes especially in New England.

No one comes to help if something goes wrong with your barn door. Most folks end up disliking the results and style.

A base roller guide is typically not included with most kits and when any guide is included, it is often just flimsy plastic or cumbersome parts that do not account for most customized situations.

Glass and metal on kit doors are often sub-par quality not formed in the USA.

Thinner metals can wobble and make your door sag or drag.

Your door does not have a story that tells you who made it and where the “wood” they used came from. A kit and a kit door was likely mass-produced by nameless, faceless low-quality labor and with no customer service for later on when something goes wrong.